Unleash Your Inner Craftsperson: Simple Woodworking Projects for Stunning DIY Furniture

Tired of mass-produced furniture? Yearning to create something beautiful and functional with your own two hands? Then dive into the rewarding world of woodworking! This article presents several easy DIY furniture projects perfect for beginners, requiring minimal tools and experience. Prepare to transform basic lumber into stylish pieces that will enhance your home and boost your confidence. Forget expensive, impersonal store-bought pieces; let's build something truly unique and personal.

A Rustic Charm: The Simple Bookshelf

Start your woodworking journey with a project that's both practical and aesthetically pleasing: a rustic bookshelf. This project utilizes basic cuts and requires minimal joinery, making it ideal for novices. You'll primarily need untreated pine boards, wood glue, screws, and a simple saw (a circular saw or hand saw will work fine). Choose attractive, slightly uneven boards for a more rustic feel. Remember to sand all surfaces smooth before assembling. Consider adding a protective stain or sealant to enhance the wood's natural beauty and durability. The entire process, from cutting to finishing, can be completed within a weekend, leaving you with a charming bookshelf ready to showcase your favorite reads.

Step-by-Step Guide:

- Cut the boards to your desired dimensions for shelves and sides. Remember to account for the thickness of the boards when determining shelf spacing.

- Apply wood glue to the ends of the shelf boards and attach them to the side pieces using screws, ensuring even spacing.

- Sand all surfaces thoroughly, paying attention to any rough edges or splinters.

- Apply a stain or sealant of your choice. Allow sufficient drying time before use.

Modern Minimalism: A Sleek Floating Shelf

For a more contemporary touch, create a sleek floating shelf. This project showcases clean lines and minimal hardware. You'll need high-quality plywood, strong wood screws, and sturdy L-brackets hidden behind the shelf. Precise measurements are crucial for this project to maintain its modern aesthetic. Before installation, carefully plan the placement to ensure it's securely mounted to a wall stud. Once installed, the floating shelf will appear to effortlessly float against your wall, providing a sophisticated storage solution.

Essential Tips:

- Use a level to ensure the shelf is perfectly horizontal.

- Pre-drill pilot holes to prevent splitting the wood when screwing in the brackets.

- Consider adding a subtle edge banding to the shelf's front for a polished finish.

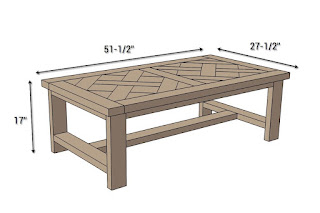

Rustic Industrial Style: A Simple Coffee Table

Embrace the industrial aesthetic with a simple coffee table built from reclaimed wood or repurposed pallets. This project involves slightly more complex joinery, but it remains achievable for beginners. Safety is paramount – always wear safety glasses and use appropriate tools. You'll need to carefully disassemble the pallet (if using one) and thoroughly clean the wood. Consider using metal hairpin legs for a distinctly industrial touch. Once assembled, the rustic coffee table will add a unique, character-filled centerpiece to your living room.

Choosing Your Materials:

- If using pallets, ensure they are properly treated and free from harmful chemicals or pests.

- Sand the wood thoroughly to remove any splinters or uneven surfaces.

- Use strong wood glue and screws to create a robust and stable table.

These are just three starting points. With a little creativity and some basic woodworking skills, you can transform simple materials into stunning, personalized furniture. So, gather your tools, choose your project, and unleash your inner craftsman!